|

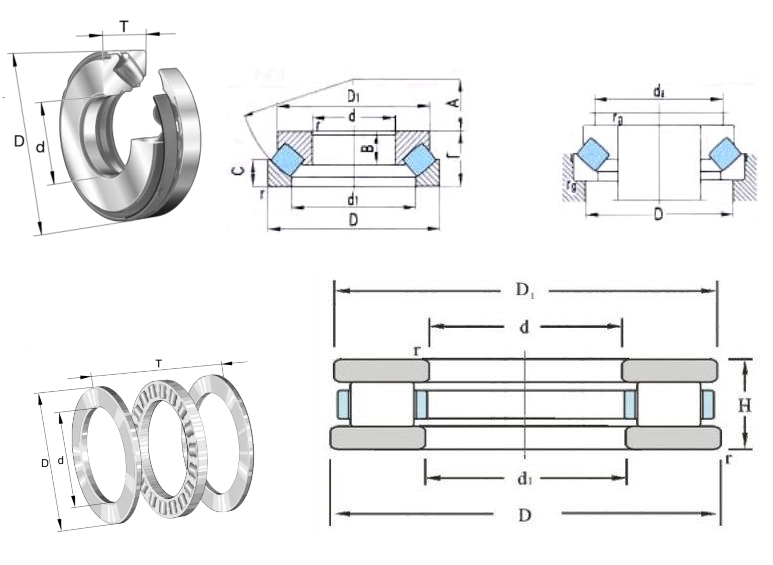

Thrust roller bearing

Collect

Thrust roller bearings are used to withstand axial and radial combined loads, but the radial load should not exceed 55% of the axial load. Compared with other thrust roller bearings, this type of bearing has a lower friction coefficient, higher speed, and self-aligning performance. The rollers of the bearing are asymmetric spherical rollers, which can reduce the relative sliding between the rollers and the raceway during operation. The rollers are long, have a large diameter, have a large number of rollers, and have a high load capacity. Oil lubrication is usually used, and in some low-speed situations, grease lubrication can be used. Thrust cylindrical roller bearings and thrust tapered roller bearings are suitable for low-speed applications, with thrust tapered roller bearings having slightly higher speeds than thrust cylindrical roller bearings. Thrust cylindrical roller bearings are separable bearings that can only withstand unidirectional axial loads and slight impacts. Thrust tapered roller bearings can only withstand unidirectional axial loads and can limit the unidirectional axial displacement of the bearing. Compared with thrust cylindrical roller bearings, they have a larger load-bearing capacity and smaller relative sliding, but have a lower limit speed.

|